check

check

check

check

The Ultimate Guide to 5V Photoelectric Sensors: How They Work and Why They’re Essential In the world of automation and industrial technology, precision and reliability are paramount. Among the many components that make modern systems efficient, the 5V photoelectric sensor stands out as a critical tool for detecting objects, measuring distances, and ensuring seamless operations. Whether you’re an engineer, a tech enthusiast, or someone curious about how machines “see,” this guide will delve into the inner workings, applications, and benefits of 5V photoelectric sensors.

A 5V photoelectric sensor is a type of optoelectronic device that uses a light source, typically an LED, and a receiver to detect objects or changes in its environment. Operating at 5 volts, these sensors are designed for low-power applications, making them ideal for portable devices, robotics, and small-scale automation systems. The sensor works on the principle of light reflection, interruption, or transmission. When an object enters the sensor’s detection range, it alters the light beam, triggering the sensor to send an electrical signal. This signal can then be used to perform specific tasks, such as stopping a conveyor belt, counting items, or activating a mechanism.

The operation of a 5V photoelectric sensor can be broken down into three main types:

Through-Beam Sensors: These consist of a separate emitter and receiver. The emitter sends a light beam to the receiver, and when an object interrupts this beam, the sensor detects its presence. Through-beam sensors are known for their high accuracy and long detection ranges.

Reflective Sensors: In this setup, the emitter and receiver are housed in the same unit. The sensor emits light, which bounces off a reflective surface or object and returns to the receiver. Reflective sensors are compact and ideal for detecting objects in confined spaces.

Diffuse Reflective Sensors: Similar to reflective sensors, diffuse sensors rely on the light reflected directly off the object itself. These are versatile and widely used in applications where the object’s surface is non-reflective or uneven.

Low Power Consumption: Operating at 5 volts, these sensors are energy-efficient, making them suitable for battery-powered devices.

Compact Design: Their small size allows for easy integration into tight spaces.

Fast Response Time: Photoelectric sensors can detect objects in milliseconds, ensuring real-time accuracy.

Durability: Built to withstand harsh environments, many models are resistant to dust, moisture, and vibrations.

The versatility of 5V photoelectric sensors makes them indispensable across various industries. Here are some of their most common applications:

Industrial Automation: From assembly lines to packaging systems, these sensors ensure precise object detection and positioning.

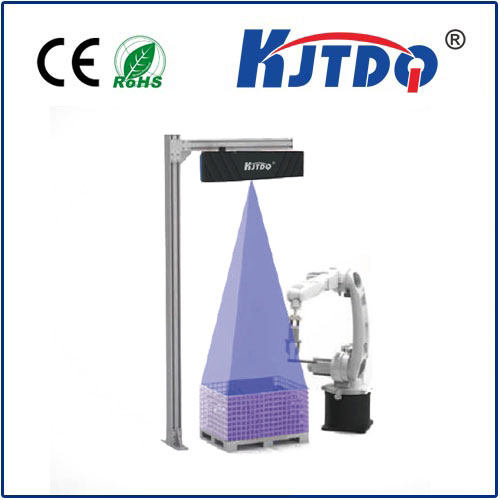

Robotics: In robotic arms and autonomous vehicles, photoelectric sensors help navigate and avoid obstacles.

Consumer Electronics: They are used in devices like printers, vending machines, and smart home systems.

Security Systems: Photoelectric sensors are integral to motion detectors and intrusion alarms.

Medical Equipment: In devices like infusion pumps and diagnostic tools, they ensure accurate measurements and operations.

The decision to use a 5V photoelectric sensor often boils down to its unique advantages:

Energy Efficiency: With the growing emphasis on sustainability, low-power sensors are a practical choice.

Cost-Effectiveness: Compared to higher-voltage sensors, 5V models are more affordable and accessible.

Ease of Integration: Their compatibility with microcontrollers and other low-voltage systems simplifies the design process.

Reliability: Photoelectric sensors are known for their consistent performance, even in challenging conditions.

When choosing a 5V photoelectric sensor, consider the following factors:

Detection Range: Ensure the sensor’s range matches your application’s requirements.

Environmental Conditions: Opt for models with protective coatings if the sensor will be exposed to dust, moisture, or extreme temperatures.

Response Time: For high-speed applications, select a sensor with a fast response time.

Output Type: Common output types include NPN, PNP, and analog. Choose one that aligns with your system’s specifications.

As technology advances, so do photoelectric sensors. Recent innovations include:

Smart Sensors: Equipped with microprocessors, these sensors can process data and communicate with other devices.

Miniaturization: Smaller sensors are being developed for use in wearable technology and IoT devices.

Enhanced Durability: New materials and designs are improving sensors’ resistance to wear and tear.

While 5V photoelectric sensors are highly reliable, they can face challenges such as:

Interference from Ambient Light: This can be mitigated by using modulated light sources or filters.

False Triggers: Proper calibration and placement can reduce the likelihood of erroneous detections.

Limited Range in Certain Conditions: For long-range applications, through-beam sensors are often the best solution.

The demand for automation, IoT, and smart technologies is driving the evolution of photoelectric sensors. Future trends include the integration of AI for advanced object recognition, the development of wireless sensors for greater flexibility, and the use of eco-friendly materials to reduce environmental impact. By understanding the principles, applications, and benefits of 5V photoelectric sensors, you can make informed decisions that enhance your projects and systems. Whether you’re optimizing an industrial process or building a cutting-edge robot, these sensors are a powerful tool in your arsenal.