KJT-AB300 series explosion-proof sound and light alarms are mainly suitable for Zone 1 or Zone 2 hazardous areas in explosive gas environments, which are explosion hazardous places of Class IIB, IIC T6 and below. They are suitable for explosive hazardous environments such as petroleum refining, storage, chemical industry, medicine, military industry and military facilities. They are used for signal alarms and signal indications in explosive gas environments.

| model | KJT-AB300 Series |

| Rated operating frequency | 50HZ |

| Rated operating voltage | AC220V;AC110V;DC36V;AC/DC24V;DC12V |

| volume | 120dB,180dB (optional) |

| Explosion proof signs | IP65 |

| Protection level | IP65 |

| Signal Color | Red, yellow, blue, green |

| Ambient humidity | 10%~95%(No condensation) |

Function

| Multi-layer explosion-proof, and certificates can be checked

|

| Installation | Wall Mount |

| Light Color | Red/Yellow/Blue/Green |

Rated Power | 120dB,10W;180dB,20W |

| Flashing frequency | 150 times/min |

The alarm can work reliably under the following conditions

A. The upper limit of the ambient air temperature does not exceed +85℃

B. The relative humidity of the air at the installation site does not exceed 50% when the maximum temperature is +40℃; higher relative humidity is allowed at lower temperatures, the average minimum temperature of the wettest month does not exceed +25℃, and the average maximum relative humidity of the month does not exceed 90%

C. In a place without severe vibration, impact and shaking

D. The pollution level is level 3

Main structure

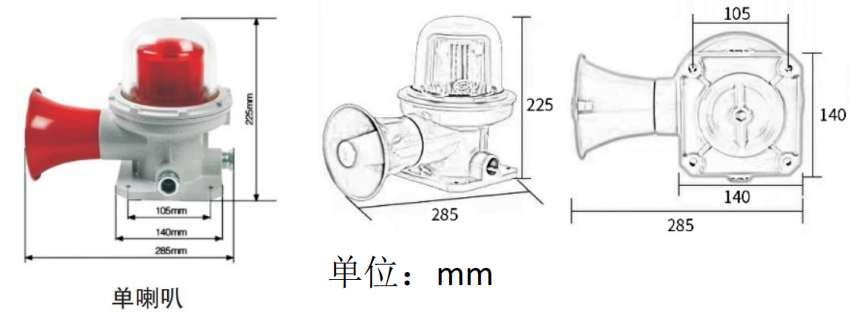

a. The alarm shell is made of aluminum alloy high-pressure casting, and the surface is high-voltage electrostatic sprayed after shot blasting

b. Lightweight structure, beautiful appearance

c. Combination of multiple explosion-proof treatment forms, reliable explosion-proof performance

d. Signal colors are available in red, yellow, blue and green

e. Steel pipe or cable wiring

Use and maintenance

a. The alarm installation form is boom type, wall type, and seat type

b. Before installation, check whether the basic data listed on the sign light nameplate conforms to the actual use

c. When the cable is introduced into the wiring, insert the compression nut, washer, and seal ring in sequence, tighten the compression nut, compress the seal ring until the cable cannot be pulled, connect the wire to the corresponding terminal according to the wiring mark, block the wire entry hole with a gasket and a seal ring, and tighten the compression nut

d. The alarm should be reliably grounded

e. When repairing, the power should be disconnected before opening the cover, and the explosion-proof surface should be protected

f. To ensure the normal operation and safety of the lamp, users should pay attention to