check

check

check

check

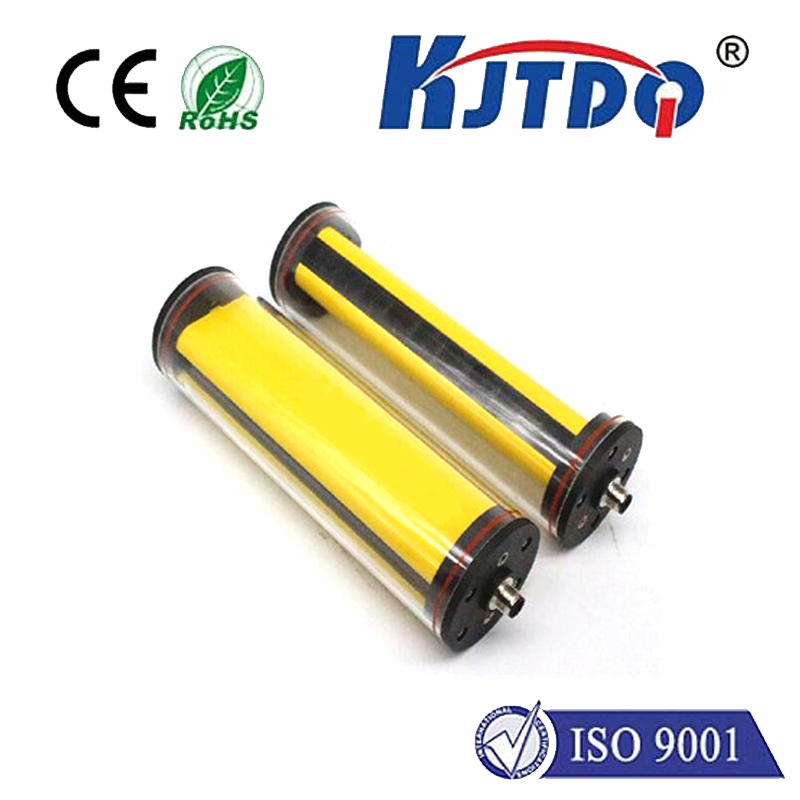

Title: Enhancing Industrial Efficiency with the E3ZM-LS82H 5M Photoelectric Sensor In the ever-evolving landscape of industrial automation, the role of sensors is paramount to ensuring seamless operation and efficiency. Among the myriad of options available, the E3ZM-LS82H 5M photoelectric sensor stands out as a reliable solution tailored to meet diverse industrial needs. This article delves into the features and applications of this advanced sensor, underscoring its importance in modern manufacturing environments. Understanding the E3ZM-LS82H 5M Photoelectric Sensor The E3ZM-LS82H 5M photoelectric sensor is a state-of-the-art device designed to detect objects within a specified range. Its name signifies its unique specifications – ‘E3ZM’ denotes the series it belongs to, ‘LS82H’ indicates the model, and ‘5M’ suggests that it operates at a distance of up to 5 meters. The sensor utilizes a non-contact optical detection method to identify changes in light intensity caused by an object’s presence or absence, making it an ideal choice for various automated systems. Key Features and Advantages One of the standout features of the E3ZM-LS82H 5M is its long detection range, which allows for versatile placement and broader application scenarios. Additionally, the sensor boasts high precision and reliability, ensuring consistent performance even in harsh industrial conditions. Its compact design facilitates easy installation in tight spaces without compromising on functionality. Furthermore, the sensor’s robust build ensures durability, reducing maintenance costs and downtime. Applications Across Industries The utility of the E3ZM-LS82H 5M photoelectric sensor spans across multiple industries. In the manufacturing sector, it plays a critical role in conveyor belt monitoring, ensuring products are correctly spaced and aligned, thereby enhancing production line efficiency. It is also widely used in packaging machinery to detect product dimensions and verify seal integrity, crucial for maintaining quality control standards. In the automotive industry, these sensors assist in robotic welding stations by detecting workpiece positions and alignment, contributing to precision and speed in vehicle assembly processes. Additionally, they serve as safety devices in machinery, preventing accidents by halting operations when an unintended object enters the hazardous zone. Conclusion The E3ZM-LS82H 5M photoelectric sensor represents a significant advancement in industrial sensing technology. Its extensive detection range, combined with its accuracy, versatility, and durability, makes it indispensable for optimizing industrial processes. As industries continue to adopt more sophisticated automation solutions, manufacturers can rely on such sensors to enhance productivity, ensure worker safety, and maintain high-quality standards in their operations. With the integration of the E3ZM-LS82H 5M photoelectric sensor, businesses can look forward to a future of streamlined operations and enhanced competitiveness in the market.