check

check

check

check

In the realm of industrial automation and safety, intrinsically safe proximity sensors play a critical role. These sensors are specifically designed to be used in hazardous environments where flammable gases, vapors, or dust might be present. Unlike conventional sensors, which could potentially ignite these elements, intrinsically safe (IS) sensors are engineered to prevent such occurrences, thereby ensuring both operational efficiency and employee safety.

The term “intrinsically safe” refers to devices that are inherently incapable of releasing sufficient electrical energy to cause an ignition in a hazardous atmosphere. This is achieved through several design principles, including:

Limited Electrical Power: IS sensors operate at very low power levels, typically less than 2 Watts. Even if the internal circuitry were to fail, the limited energy available would not be enough to spark an explosion.

Restricted Thermal Energy: The components within intrinsically safe sensors are designed to maintain surface temperatures below the ignition points of common flammable materials.

Galvanic Isolation: Many IS sensors incorporate barriers, such as opto-isolators or transformers, that ensure no direct electrical path exists between the sensor and its control system. This mitigates the risk of spark generation.

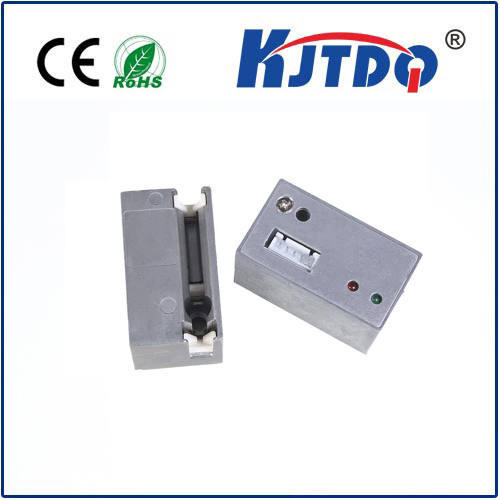

Robust Enclosure: The physical design includes strong, sealed casings that protect against environmental factors while also preventing the escape of any internal faults that could cause ignition.

Due to their unique safety features, intrinsically safe proximity sensors are indispensable in industries where explosive risks are prevalent. Key sectors include:

Oil and Gas: Used in drilling rigs, refineries, and offshore platforms to monitor equipment status without compromising safety.

Chemical Processing: Vital for controlling reactions and ensuring leak detection in chemical plants where volatile substances are handled.

Food Production: Employed in environments with flour dust or other combustible materials to maintain hygiene standards and prevent contamination-related incidents.

Pharmaceuticals: Used in cleanroom settings to monitor door positions, product flow, and machinery operation without introducing contamination or fire risks.

Choosing the appropriate IS sensor involves considering several factors:

Explosion-Proof Rating: Different regions have specific certification standards (such as ATEX in Europe or IECEx globally), and it’s crucial to select a sensor compliant with the local regulations.

Detection Range and Type: Proximity sensors vary in their operating principles (capacitive, inductive, optical) and detection ranges. Matching the sensor type to the target material and required distance is essential for optimal performance.

Mounting Options: Depending on the installation environment, sensors may need to be flush-mounted, pipe-mounted, or adapted for specific machine designs.

Connectivity and Compatibility: Ensure the sensor integrates seamlessly with your existing control systems and communication protocols, whether that’s analog outputs, digital signals, or smart networking capabilities. In conclusion, intrinsically safe proximity sensors are a cornerstone of modern industrial safety practices, especially in high-risk environments. Their specialized design not only adheres to stringent safety standards but also enhances operational reliability and productivity across various industries. By understanding the principles behind these sensors and carefully selecting the right model for your application, you can significantly mitigate safety hazards while maintaining smooth and efficient operations.