check

check

check

check

In today’s industrial landscape, automation has become a cornerstone for efficiency and productivity. Central to this automation revolution is the proximity sensor, particularly the 24V variant. This article delves into the significance, benefits, and diverse applications of the 24V proximity sensor.

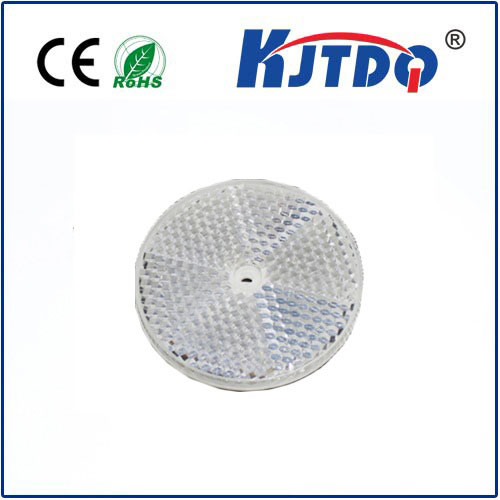

A 24V proximity sensor operates at a voltage of 24 volts and is utilized to detect the presence or absence of an object without any physical contact. These sensors come in various types, including capacitive, inductive, and photoelectric, each suited to different operational needs. Their compact size, reliable performance, and ease of integration make them indispensable across multiple industries.

The adoption of 24V proximity sensors offers numerous advantages:

Enhanced Safety: By enabling non-contact detection, these sensors minimize wear and tear on machinery and ensure worker safety by preventing direct human-machine interaction.

Increased Efficiency: Automating detection processes leads to streamlined operations, reducing downtime and increasing overall productivity.

Versatility: Available in different sensing modes (capacity, induction, light), 24V proximity sensors can be tailored to suit specific requirements, from metal detection to identifying transparent objects.

Cost-Effectiveness: Despite their advanced technology, these sensors are affordable and require minimal maintenance, offering a cost-efficient solution for various applications.

Durability: Designed to withstand harsh environmental conditions, they boast high durability, thereby ensuring longevity and consistent performance.

The application scope of 24V proximity sensors spans various domains due to their adaptability and reliability:

Manufacturing: In production lines, proximity sensors monitor the movement of products, control conveyor belts, and ensure proper assembly sequences.

Automotive Industry: They play a crucial role in automated guided vehicles (AGVs) and in monitoring parts during manufacturing and assembly processes.

Hydraulic Systems: Proximity sensors are employed to measure fluid levels accurately in reservoirs, tanks, or cylinders, ensuring optimal system performance.

Packaging Machines: These sensors assist in counting items, checking fill levels, and ensuring correct product alignment, which are essential for efficient packaging processes.

Robotics: In robotic automation, 24V proximity sensors help robots navigate through their surroundings by detecting objects and obstacles to prevent collisions and optimize paths.

The 24V proximity sensor stands as a testament to the advancements in sensor technology, offering a blend of safety, efficiency, versatility, cost-effectiveness, and durability. Its wide range of applications underscores its importance in modern industries aiming for automation and precision. Investing in these sensors not only enhances operational performance but also paves the way for future innovations and improvements in process control.