check

check

check

check

Understanding the Diverse Types of Proximity Switches Proximity switches are essential components in automation and control systems, enabling machines to detect the presence or absence of nearby objects without physical contact. These devices operate based on various principles and come in different types to suit specific applications. In this article, we will explore the main types of proximity switches, their characteristics, and typical use cases.

Inductive proximity switches operate on the principle of electromagnetic induction. They contain a coil that generates an oscillating magnetic field when energized. When a metallic object comes within the range of this field, it disrupts the electromagnetic field and causes a change in the oscillation frequency. This change is detected by the switch, triggering an output signal.

These switches are commonly used in environments where the target object is metallic. Industries such as automotive manufacturing, packaging, and conveyor systems benefit from inductive proximity switches due to their robustness and reliability.

Capacitive proximity switches work on the principle of capacitance variation. They consist of a dielectric material between two conductive plates. When an object (regardless of whether it is metallic or not) approaches the switch, it alters the capacitance between the plates. This change in capacitance is converted into an electrical signal to indicate the object’s presence.

These switches are versatile and widely used in liquid level detection, product counting, and position sensing applications in industries such as food and beverage, chemical processing, and pharmaceuticals.

Magnetic proximity switches rely on the interaction between a magnetic field and a reed switch inside the sensor. The presence of a magnetic object alters the state of the reed switch, either opening or closing it, depending on its design.

These switches are particularly useful in environments where there is a requirement for explosion-proof devices or when working with ferrous materials. They are commonly found in mining operations, metal fabrication processes, and any scenario requiring non-contact switching in harsh conditions.

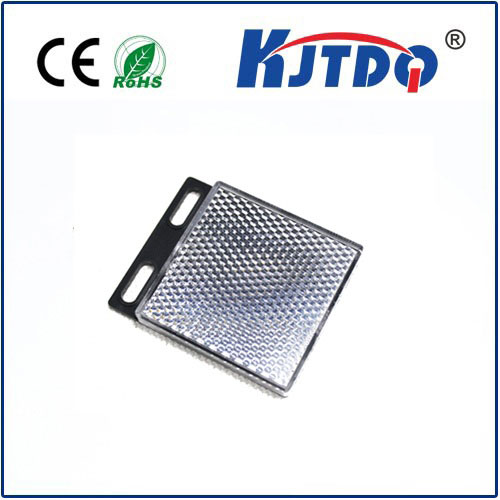

Photoelectric proximity switches function by using a light beam to detect objects. A transmitter emits a beam of light towards a receiver. When an object interrupts this beam, the receiver senses the change and generates an electrical signal indicating the object’s presence.

These switches are ideal for detecting non-metallic objects and are extensively used in automated assembly lines, sorting mechanisms, and robotics for accurate object detection and positioning.

Ultrasonic proximity switches utilize sound waves to detect objects. An ultrasonic wave is sent out, and if an object is present, the wave bounces back and is detected by the receiver element of the switch.

These switches are suitable for long-distance detection, making them valuable in parking management systems, security alarms, and automatic doors where large areas need monitoring without physical contact.

Each type of proximity switch has unique features that make it suitable for specific application scenarios. Whether it’s the durability and simplicity of inductive proximity switches, the versatility of capacitive ones, the ruggedness of magnetic switches, the precision of photoelectric ones, or the long-range detection capabilities of ultrasonic switches, understanding the differences helps in selecting the right tool for your automation needs. By choosing the appropriate type of proximity switch, you can enhance the efficiency and reliability of your systems.