check

check

check

check

FRS Series Rotary Limit Switches: Reliable and Versatile for Precision Control When it comes to ensuring precise control in industrial applications, the FRS series rotary limit switches stand out as reliable and versatile components. These devices are specifically designed to provide accurate feedback on the position or movement of a rotating shaft, making them essential for machinery that requires precise motion control.

The FRS series offers several advantages that make it a top choice for various industries:

High Accuracy and Reliability: The primary function of any limit switch is to ensure that machinery operates within safe parameters. FRS series rotary limit switches deliver high accuracy, which means they can detect even the slightest deviations from the set positions, ensuring consistent performance and safety.

Durability: Manufactured with high-quality materials, these limit switches are built to withstand harsh industrial environments, including exposure to dust, moisture, and varying temperatures. This durability makes them ideal for use in demanding settings where reliability is crucial.

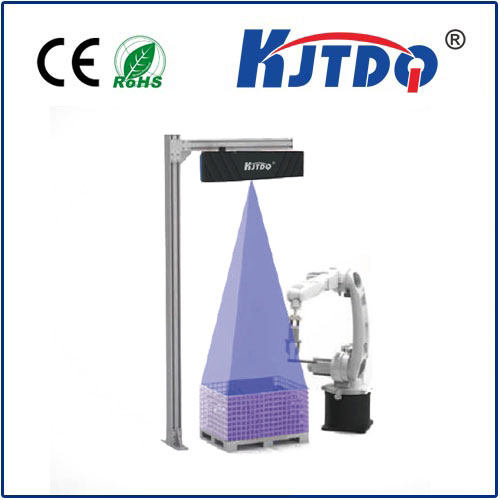

Versatility in Applications: Whether you’re working with conveyor systems, packaging machinery, or robotic arms, the FRS series provides solutions tailored to meet diverse requirements. Their adaptability extends to different types of rotary movements, including continuous and oscillating motions, offering broad application potential.

Ease of Installation: Installing an FRS series rotary limit switch is straightforward, thanks to their user-friendly design. This ease of installation reduces downtime and ensures quick integration into existing systems, enhancing overall operational efficiency.

To understand why the FRS series stands out, let’s delve into some of its key features:

Adjustable Actuators: These switches come with adjustable actuators, allowing users to fine-tune the activation point according to specific needs. This adjustability is crucial for applications requiring exact control over machine operations.

Multiple Contact Options: Depending on the complexity of the system and required level of redundancy, FRS series switches offer various contact configurations. These include single pole (SP), double pole (DP), and changeover (CO) options, providing flexibility to meet different control requirements.

IP Rating Compliance: With a robust IP rating, these limit switches ensure protection against ingress of dust and water, making them suitable for outdoor and washdown applications where environmental conditions can be challenging.

Mechanical and Electrical Lifespan: Designed for longevity, FRS series switches boast impressive mechanical and electrical lifespans, ensuring that they perform reliably over extended periods without frequent maintenance or replacement.

FRS series rotary limit switches find extensive use across various industries due to their precision and reliability. Here are a few practical applications:

Conveyor Systems: Ensuring that conveyor belts stop at precise points for loading or unloading materials.

Robotics: Providing feedback for the correct positioning of robotic arms in assembly lines.

Packaging Machinery: Monitoring the rotation of packaging units to guarantee proper sealing and cutting.

Automated Gates: Controlling the opening and closing positions of gates to prevent overextension or jamming.

In conclusion, the FRS series rotary limit switches represent a pinnacle of precision control and reliability in industrial automation. Their robust construction, high accuracy, and versatility make them indispensable components for any machinery requiring meticulous control over rotary movements. By choosing the FRS series, industries can enhance operational efficiency, ensure worker safety, and achieve greater productivity in their processes.