NSR66-PS Belt Position Switch

- time:2024-10-29 08:31:52

- Click:0

Title: Understanding the NSR66-PS Belt Position Switch and Its Vital Role in Modern Machinery

Introduction:

In the world of industrial machinery, switches play an integral role in ensuring the seamless operation of complex systems. Among these, the NSR66-PS Belt Position Switch stands out for its reliability and precision in monitoring conveyor belt positions. This article delves into the significance of the NSR66-PS Belt Position Switch, exploring its design, function, and the benefits it brings to modern machinery management.

What is the NSR66-PS Belt Position Switch?

The NSR66-PS Belt Position Switch is a sophisticated device specifically designed to detect the presence and position of conveyor belts within material handling systems. It functions by sensing changes in the magnetic field generated by the movement of metal objects, such as belts or other components, through its sensing range. This information is crucial for maintaining optimal performance and safety in industrial processes.

Design and Technology:

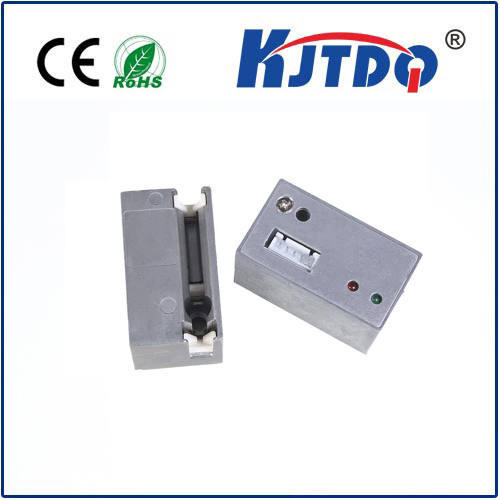

Crafted with advanced technology, the NSR66-PS boasts a robust construction capable of withstanding the harsh environments typically encountered in industrial settings. Its compact size allows for easy installation and integration into existing systems without causing disruptions. The switch features an adjustable sensing distance, permitting fine-tuning according to specific application requirements. Furthermore, its IP-rated enclosure ensures protection against dust and moisture, enhancing longevity and reliability.

Key Features:

- High Sensitivity: The NSR66-PS provides precise detection even at high speeds, making it ideal for fast-moving conveyor systems.

- Versatility: Suitable for various types of conveyors, including those made from different materials like steel or aluminum.

- Easy Installation & Maintenance: User-friendly setup process and low maintenance needs reduce downtime and operational costs.

- Durability: Robust build quality assures long-term service life under challenging conditions.

- Customizability: Adjustable sensitivity settings cater to diverse applications, ensuring optimal performance in every scenario.

Benefits of Using the NSR66-PS Belt Position Switch:

- Enhanced Safety: By accurately monitoring belt positions, potential misalignments that could lead to accidents are promptly identified and corrected, safeguarding personnel and equipment.

- Increased Efficiency: Smooth operation of conveyor systems minimizes material waste and improves overall production efficiency, translating into cost savings.

- Preventative Maintenance: Early detection of issues enables proactive maintenance strategies, extending the lifespan of conveyor systems and reducing unexpected breakdowns.

- Customization: The ability to adjust sensitivity settings ensures the switch can be tailored to meet the unique demands of each application, optimizing performance.

- Reliability: Proven track record of durability and dependability ensures continuous operation without frequent replacements or repairs.

Conclusion:

In conclusion, the NSR66-PS Belt Position Switch epitomizes innovation in industrial automation, offering unparalleled accuracy and reliability in conveyor belt positioning. Its adoption not only enhances operational safety but also drives efficiency and sustainability in modern manufacturing environments. As industries continue to evolve towards smarter solutions, the NSR66-PS remains at the forefront, empowering businesses to operate safely, efficiently, and sustainably.