check

check

check

check

check

check

check

check

check

check

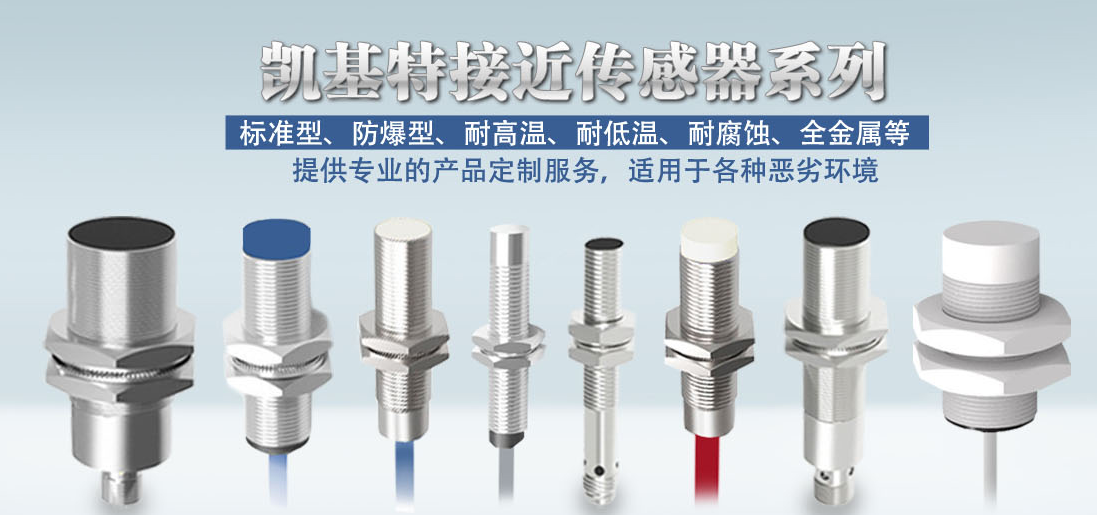

Title: Understanding the Range of Inductive Proximity Sensors Inductive proximity sensors are widely used in industrial automation and other applications to detect the presence of metallic objects without any physical contact. The range of these sensors is a crucial factor that determines their effectiveness in various applications. In this article, we will discuss the range of inductive proximity sensors and how it affects their performance. What is an Inductive Proximity Sensor? An inductive proximity sensor is a type of proximity sensor that uses electromagnetism to detect the presence of a metal object. It consists of a coil that produces a magnetic field when an electric current passes through it. When a metal object comes close to the sensor, the magnetic field is disturbed, and the sensor detects this change. The sensor then generates an output signal that indicates the presence of the metal object. Factors Affecting the Range of Inductive Proximity Sensors The range of an inductive proximity sensor refers to the maximum distance from which it can detect a metal object. Several factors affect this range, including: