check

check

check

check

In the rapidly advancing field of technology, precise measurements are crucial for a wide range of applications. Measurement transducers play a vital role in this process, serving as the bridge between the physical world and the digital realm. This article explores the significance of measurement transducers and their diverse applications across various industries.

A measurement transducer is a device that converts one form of energy into another while retaining the essential information about the measurand, such as temperature, pressure, force, or displacement. These devices consist of three main components: the sensor element, the transducer element, and the output signal processor. The sensor element detects the physical quantity to be measured, the transducer element converts this quantity into a different form of energy, and the output signal processor amplifies and conditions the signal for further analysis.

There are several types of measurement transducers available today, each designed to measure specific physical quantities. Some of the most common types include:

Thermocouples: Used for measuring temperature by converting thermal energy into electrical signals.

Strain Gauges: Commonly used in load cells and accelerometers to measure force, pressure, or deformation.

Pressure Transducers: Convert pressure variations into electrical signals for monitoring fluid levels or gas pressures.

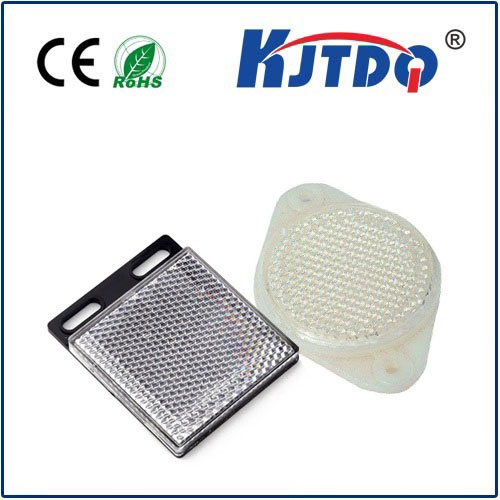

Proximity Sensors: Detect the presence or distance of an object without any physical contact.

Accelerometers: Measure linear acceleration or vibrations in various industrial and automotive applications.

Laser Doppler Vibrometers: Utilize laser light to非接触式测量物体的表面速度和振动。

Measurement transducers find applications in virtually every industry imaginable, from healthcare and aerospace to manufacturing and environmental monitoring. Some notable examples include:

Medical Devices: Measurement transducers are used in various medical devices such as blood pressure monitors, electrocardiogram (ECG) machines, and respiratory rate monitors to provide accurate patient data for diagnosis and treatment.

Automotive Industry: Measurement transducers play a critical role in the automotive industry, where they are used in airbag systems, engine management systems, and advanced driver assistance systems (ADAS) to enhance vehicle safety and performance.

Manufacturing and Industrial Automation: In manufacturing plants and industrial facilities, measurement transducers are employed in process control systems to monitor and regulate variables such as temperature, pressure, flow rate, and humidity to ensure consistent product quality and optimize生产效率。

Environmental Monitoring: Measurement transducers are essential tools in environmental monitoring applications, where they are used to measure air quality parameters like carbon dioxide levels, humidity, and particulate matter concentration to help protect public health and the environment.

The use of measurement transducers offers numerous advantages over traditional manual measurement methods:

Accuracy and Precision: Measurement transducers provide highly accurate and precise measurements, reducing human error and improving overall reliability.

Real-Time Data Collection: With advancements in digital technology, many measurement transducers now come with built-in data processing capabilities that allow for real-time data collection and analysis.

Versatility: Measurement transducers can be customized to measure a wide range of physical quantities, making them suitable for various applications across different industries.

Cost-Effectiveness: By automating measurement processes, businesses can save time and resources, leading to increased productivity and reduced operational costs.

In conclusion, measurement transducers have become indispensable tools in modern technology, enabling precise measurements across a myriad of applications. As technology continues to evolve at an unprecedented pace, so too will the demand for innovative measurement solutions that can keep up with our ever-changing needs.