check

check

check

check

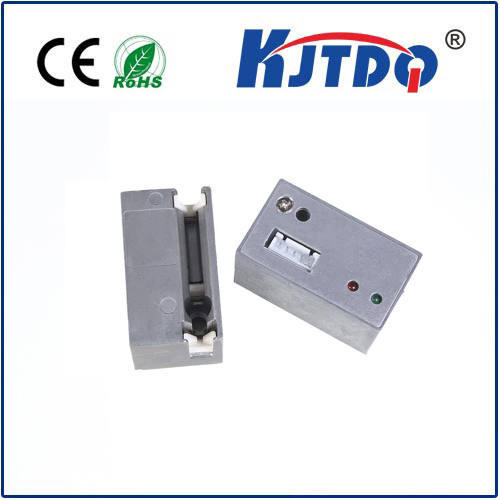

**Title: Introduction to YHP-20-35 Belt Sway Switches**

In the industrial realm, ensuring the seamless operation of conveyor belts is paramount. One critical component that safeguards such operations is the YHP-20-35 Belt Sway Switches, devices designed to detect misalignment in conveyor belts and prevent potential accidents or disruptions. This article delves into the features, working principles, installation guidelines, and applications of these indispensable switches.

YHP-20-35 Belt Sway Switches are engineered to provide high precision in detecting belt misalignment. They are equipped with two stages of action, each stage set to activate at different angles of deviation—12° for a preliminary signal and 30° for a full stop command, ensuring a graded response to belt movement anomalies. This dual-action feature is crucial for maintaining both safety and continuous workflow on conveyor systems.

The operational efficiency of YHP-20-35 Belt Sway Switches hinges on their robust construction and reliable performance under varied environmental conditions. Constructed from high-strength materials and enclosed in an IP65-rated casing, these switches are resistant to dust, moisture, and vibrations, making them suitable for harsh industrial environments. Their ability to function within a wide voltage range (24~380V) further enhances their versatility across different industrial settings.

Installation of YHP-20-35 Belt Sway Switches is straightforward yet vital for optimal performance. Properly positioning the switch along the conveyor belt, with attention to alignment and distance from the belt edge, is essential for accurate detection and timely responses. The manufacturer's guidelines recommend mounting the switches approximately 1 to 3 meters from the tail end of the belt conveyor, with a suggested spacing of one pair every 50 meters along the belt length.

These switches find extensive application in industries where conveyor belts play a significant role, such as mining, quarrying, material handling, and wastewater treatment facilities. By preventing belt misalignment, YHP-20-35 switches contribute to the protection of conveyor belts from damage, reduce downtime, and ensure the safe transport of materials without spillage or accidents.

In summary, the YHP-20-35 Belt Sway Switches are indispensable tools in the arsenal of industrial safety and efficiency. They offer a blend of reliability, ease of installation, and adaptability to various environmental conditions. Whether tasked with preventing accidents or ensuring seamless material transportation, these switches are integral to the smooth operation of any conveyor system.