check

check

check

check

Title: Understanding the Role of Ramps, Endstops, and Limit Switches in Machine Design

Introduction

Machine design is a crucial aspect of modern manufacturing processes. It involves the creation and implementation of various components that work together to ensure the smooth operation of machines. Among these components, ramps, endstops, and limit switches play a vital role in determining the movement range and precision of machines. In this article, we will delve into the significance and function of each component in the context of machine design.

Ramps

A ramp is an inclined surface or structure that facilitates the transition between different levels of a machine's operation. They are often used in conveyor systems, material handling equipment, and other industrial machinery. Ramps allow for seamless movement of products or components from one level to another without any damage or loss of control. In addition to providing a smooth transition, ramps also help reduce the strain on the machine's motor by distributing the load evenly across its length. This not only enhances the efficiency of the machine but also extends its lifespan.

Endstops

Endstops are devices that determine the maximum travel distance of a machine's moving parts. They work by sending an electrical signal to the control system when the machine reaches its predefined limits. This signal prevents further movement beyond those limits, thus avoiding potential collisions or accidents that could lead to costly repairs or downtime. Endstops come in various types, including mechanical, optical, and magnetic, each with their unique advantages and disadvantages based on the specific application requirements.

Limit Switches

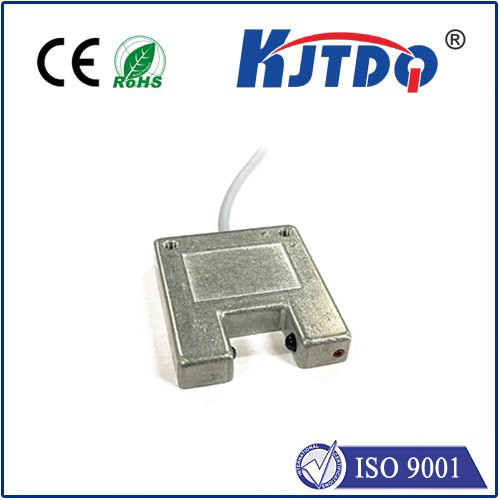

Limit switches serve a similar purpose as endstops but are more commonly used in industrial settings where precise positioning is required. Unlike endstops, which can be triggered by physical contact, limit switches use sensors to detect the presence or absence of objects within their detection range. When an object reaches a certain position, it triggers a change in the limit switch's state, which can then be communicated to the control system. This allows for precise control over the machine's movements and ensures that it operates within safe parameters at all times.

Conclusion

In conclusion, ramps, endstops, and limit switches are essential components in machine design that help regulate the movement and positioning of machines. While each plays a unique role in ensuring smooth operation and safety, they work together to create a cohesive system that meets the demands of modern manufacturing processes. As technology continues to evolve, it is likely that we will see new advancements in these components that further enhance their capabilities and improve overall machine performance.