check

check

check

check

The Importance of Limit Switch Cables in Industrial Settings

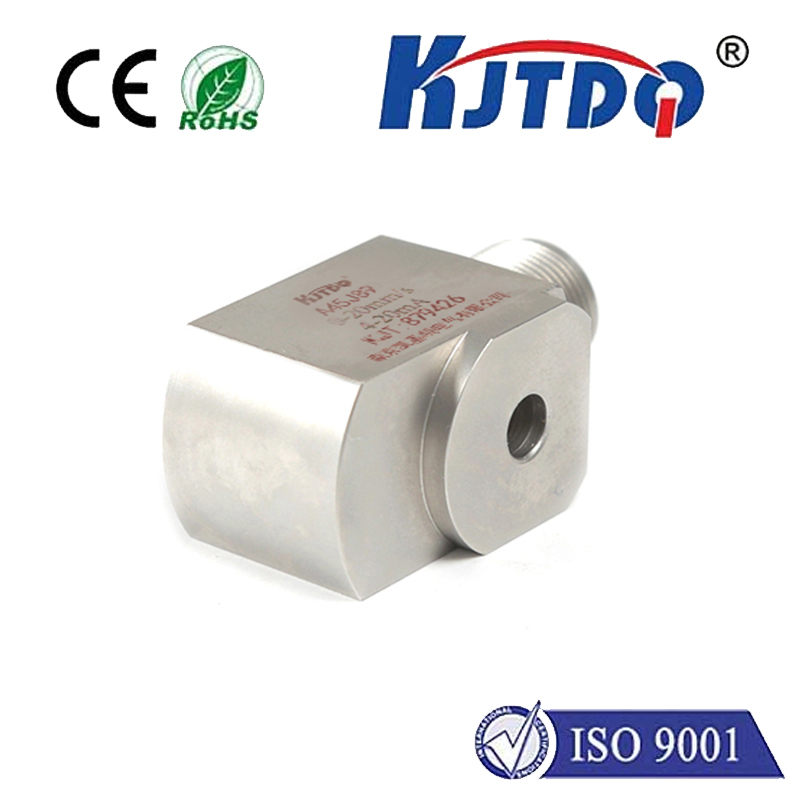

Limit switch cables are an integral component in industrial settings, particularly in machinery and equipment that require precise control over motion. A limit switch is essentially a mechanical device that detects the presence or absence of an object, and when triggered, activates or deactivates a particular function within a system. The cable connecting the switch to the control panel is what we refer to as a limit switch cable. This article will explore the significance of limit switch cables in industrial applications.

Firstly, let's understand the basic functionality of a limit switch. When an object comes into contact with the actuator on the switch, it sends a signal through the cable to the control panel. This signal triggers a specific reaction, such as stopping or starting a machine, opening or closing a valve, or any other programmed response. Without this crucial component, machines would not be able to operate autonomously or safely.

Limit switch cables play a vital role in ensuring reliable communication between the switch and the control panel. These cables must be durable enough to withstand harsh industrial environments while maintaining optimal conductivity for seamless signal transmission. High-quality materials used in these cables prevent interference from external sources like electromagnetic fields and temperature fluctuations.

Moreover, the installation of limit switch cables requires precision to avoid potential errors in signal detection. Proper placement ensures that the cables are protected from physical damage and environmental hazards which could compromise their performance. Maintenance teams also need to regularly inspect these cables for any signs of wear or damage to prevent unforeseen downtime.

In terms of safety, limit switch cables are crucial for preventing accidents in industrial settings. They provide a fail-safe mechanism that stops machinery before it causes harm to operators or damages products. For instance, if a packaging machine detects an obstruction via its limit switch, it can immediately halt operations, saving both time and resources by avoiding further complications.

Lastly, limit switch cables contribute to efficiency and productivity in manufacturing processes. By ensuring consistent machine performance, they help maintain production schedules and minimize waste caused by faulty operations. Their reliability allows for automated processes that can run continuously without human intervention, thus reducing labor costs and improving output rates.

In conclusion, limit switch cables are essential components in industrial applications due to their critical role in controlling machinery and preserving safety measures. Their durability, precise installation needs, and importance in accident prevention underscore their value in maintaining efficient operations. As industries continue to embrace automation and smart technologies, the demand for reliable limit switch cables will only increase, making them an indispensable part of modern industrial infrastructure.