check

check

check

check

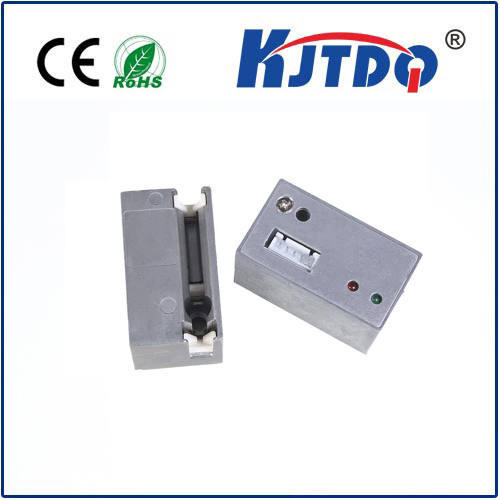

Contactless Limit Switch: Enhancing Efficiency and Reliability in Industrial Automation

The world of industrial automation is constantly evolving, driven by the need to increase productivity, improve safety, and enhance reliability. In response to these demands, innovative technologies like the contactless limit switch have emerged as game-changers, redefining how machines operate and interact within a manufacturing ecosystem.

What is a Contactless Limit Switch?

A contactless limit switch is an advanced sensor technology that detects the presence or absence of an object without any physical contact between the sensor and the target. Unlike traditional mechanical switches that rely on direct contact, contactless switches use magnetic fields, light beams, or sound waves to perform their function, eliminating the wear and tear associated with mechanical switching.

Key Benefits of Contactless Limit Switches

One of the most significant advantages of contactless limit switches is their durability. Since there are no moving parts or contacts rubbing against each other, they are less prone to wear and damage over time. This feature makes them ideal for high-vibration environments and applications requiring frequent cycling.

Another benefit is their increased reliability. Contactless switches are less affected by environmental factors such as dust, dirt, moisture, or corrosion, which can compromise the performance of traditional switches. As a result, they reduce downtime and maintenance costs in industries where cleanliness and reliability are paramount.

Furthermore, contactless limit switches offer improved accuracy and repeatability. With precise sensing capabilities, these devices ensure that machinery operates exactly as intended, leading to higher quality products and reduced waste from errors.

Applications of Contactless Limit Switches

Contactless limit switches have found widespread applications across various industries. For example, in packaging equipment, they can monitor conveyors to ensure items are properly positioned before sealing or labeling processes. In robotics, they provide crucial feedback for precision movements and endpoint detection. Additionally, in material handling systems, they can detect the presence of pallets or containers for automated sorting and routing.

In conclusion, the contactless limit switch represents a leap forward in the world of industrial automation. Its ability to provide reliable, durable, and precise sensing without physical contact not only enhances efficiency but also ensures safer working conditions by reducing maintenance needs and potential points of failure. As industries continue to push the boundaries of what's possible, contactless limit switches stand out as a key component in achieving seamless automation and optimized production processes.