check

check

check

check

Understanding Compressor Limit Switch: A Guide to its Importance and Functionality

A compressor limit switch is an essential component in the operation of a compressor system. It plays a vital role in ensuring the safety, efficiency, and reliability of the system by monitoring and regulating the pressure levels within the compressor. In this article, we will explore the importance and functionality of a compressor limit switch.

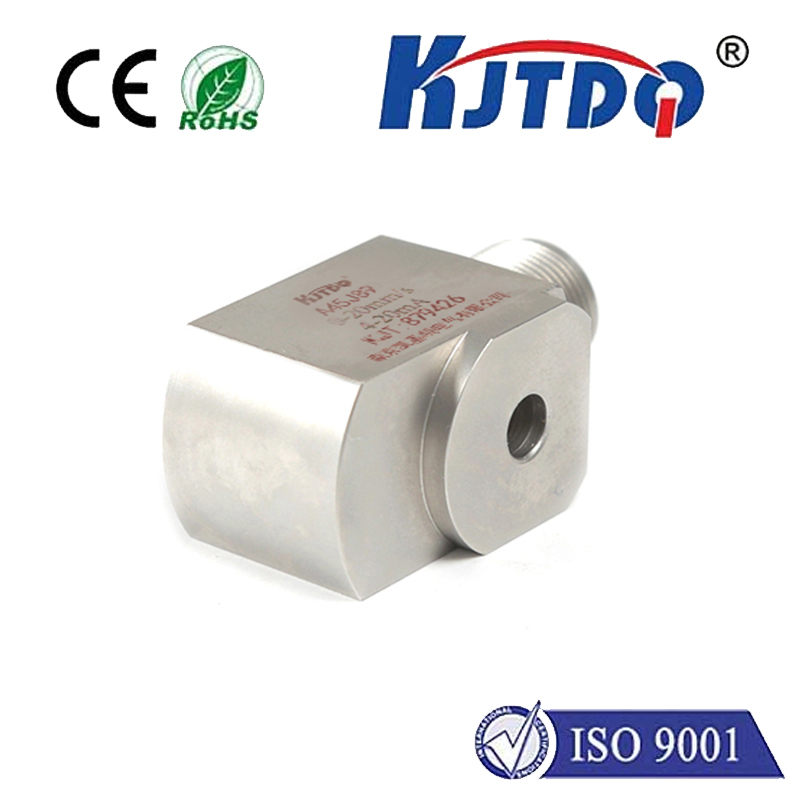

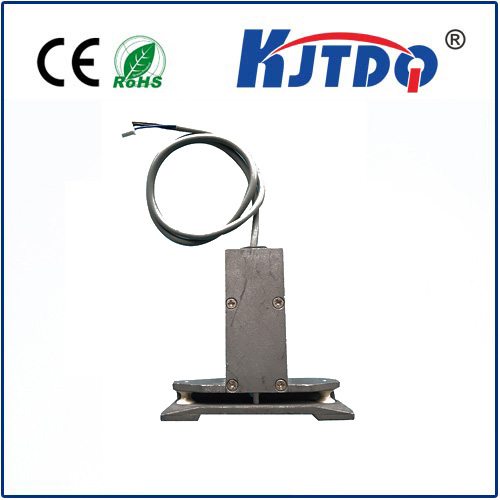

Firstly, let us define what a compressor limit switch is. A compressor limit switch is a type of pressure switch that is designed to turn off the compressor when the pressure reaches a certain set point. The switch is typically mounted on the discharge side of the compressor and consists of a diaphragm or piston that is sensitive to changes in pressure.

The primary function of a compressor limit switch is to prevent overpressurization of the compressor system. If the pressure exceeds the maximum allowable limit, it can cause damage to the compressor components and pose a safety hazard to the operators. By detecting and responding to changes in pressure, the limit switch can automatically shut down the compressor and prevent any potential harm.

In addition to safety, a compressor limit switch also helps to improve the efficiency and reliability of the system. By maintaining a consistent pressure level, the compressor can operate at optimal performance and reduce energy consumption. This not only saves costs but also extends the lifespan of the compressor components.

Furthermore, a compressor limit switch can be used to control the flow of air or gas through the system. For example, if the pressure drops below a minimum threshold, the limit switch can trigger the compressor to start up again, ensuring a continuous supply of air or gas for downstream processes.

When selecting a compressor limit switch, there are several factors to consider. Firstly, you need to determine the maximum and minimum pressure limits for your specific application. Secondly, consider the type of switch that best suits your needs, including mechanical, electronic, or pneumatic switches. Finally, ensure that the switch is compatible with your compressor system and meets any relevant safety standards and regulations.

In conclusion, a compressor limit switch is a critical component in any compressor system. It plays a vital role in preventing overpressurization, improving efficiency, controlling flow rates, and ensuring safe operation. By understanding its importance and functionality, you can make informed decisions when selecting and maintaining a compressor limit switch for your specific application.