check

check

check

check

Title: Understanding the Vital Role of Limit Switches in Bar Bending Machines

When it comes to manufacturing processes, precision is key. This holds true especially for operations involving bar bending machines, which rely on exact measurements and movements to produce quality end products. One of the crucial components that ensures this accuracy is the limit switch. In this article, we will delve into the importance of limit switches in bar bending machines and how they contribute to the overall performance and output of these machines.

The Function of a Limit Switch:

A limit switch in a bar bending machine acts as an electronic device that signals when the machine's mechanical motion reaches a specific point. These switches are typically installed at the ends of the travel paths of moving machine parts to regulate their movement and prevent collisions or overruns. As such, the limit switch effectively serves as an 'on' or 'off' indicator for the machine's control system, helping to automate and streamline the bending process.

Enhancing Safety and Accuracy:

Safety is always paramount in industrial environments, and limit switches play an indispensable role in ensuring operator safety around bar bending machines. By automatically halting the machine once a certain point is reached – preventing overtravel – damage to the machine components or potential harm to workers is minimized. Moreover, the precise stopping point indicated by the limit switch guarantees accurate bending angles and dimensions, thus maintaining product quality standards consistently.

Maintaining Efficiency:

In production settings where time is money, limit switches help maintain operational efficiency. They eliminate the need for manual intervention to check positions or stop the machine, thereby reducing setup times and increasing throughput. The consistent feedback provided by limit switches also aids in troubleshooting, as any inconsistencies in the machinery can be promptly identified and rectified.

Simplifying Maintenance:

Regular maintenance is essential for the longevity and reliability of bar bending machines. Limit switches simplify this task by providing clear diagnostic cues about the machine’s operation. If a limit switch fails to activate or sends incorrect signals, it quickly alerts technicians to the presence of a problem that requires attention, making maintenance more targeted and efficient.

Upgrading with Technology:

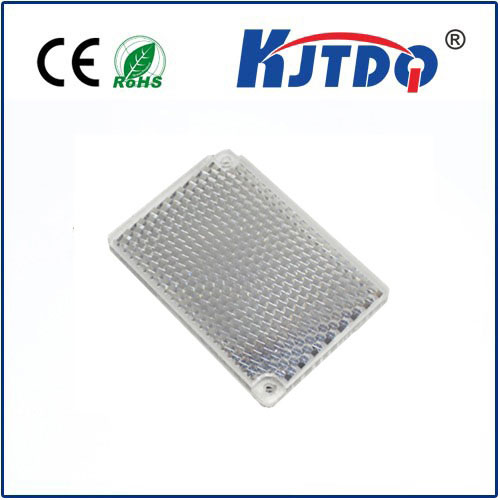

With advancements in technology, there are now various types of limit switches available, including proximity sensors and optical switches, offering greater reliability and sensitivity than traditional mechanical switches. These modern alternatives provide enhanced performance and often have longer lifespans, making them a smart investment for businesses looking to upgrade their bar bending machines.

Conclusion:

Limit switches might appear small, but their impact on the functionality of bar bending machines is immense. Ensuring safety, accuracy, and efficiency, these devices are integral to the smooth operation of any facility that relies on bar bending equipment. By understanding the critical role limit switches play, manufacturers can make informed decisions on machine maintenance and upgrades, ultimately driving up productivity and profitability.