check

check

check

check

Title: The Importance of Safety Rated Limit Switches in Industrial Settings

Safety is always a top priority in industrial settings, where heavy machinery and automated systems are often utilized to perform complex tasks. One crucial component that plays a significant role in ensuring the safety of both equipment and personnel is the safety rated limit switch. This article will highlight the importance of using safety rated limit switches and how they contribute to creating a safer working environment.

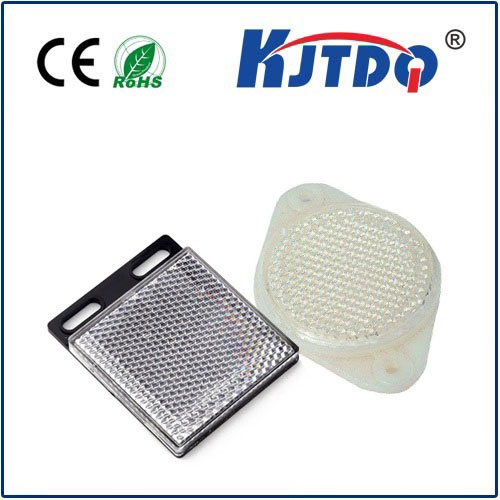

Firstly, let us understand what a safety rated limit switch is. A limit switch is an electrical device used to detect the presence or absence of an object, which can be either mechanical or optical. It consists of an actuator that activates when it comes into contact with an object, sending a signal to stop or start a process. A safety rated limit switch, on the other hand, has been designed and tested to meet specific safety standards, making it suitable for applications where human safety is involved.

In industrial settings, limit switches are commonly used to monitor the position of machinery parts, ensuring they do not exceed their operating limits. For example, if a conveyor belt is moving materials from one location to another, limit switches can be installed at the beginning and end of the conveyor belt to prevent over-travel and collisions. However, if these limit switches are not safety rated, they may fail to operate correctly, leading to potential accidents and injuries.

Safety rated limit switches provide an extra layer of protection by meeting strict safety standards. These switches undergo rigorous testing to ensure they can withstand harsh environments and operate reliably under various conditions. They also have built-in features such as redundant contacts and self-monitoring circuits to detect any faults or failures promptly. By using safety rated limit switches, industries can reduce the risk of accidents and protect both their equipment and employees from harm.

Furthermore, using safety rated limit switches can help industries comply with regulations and standards set by government agencies and accreditation organizations. Many industries are required to adhere to specific safety requirements, such as those outlined in the Occupational Safety and Health Administration (OSHA) guidelines or International Organization for Standardization (ISO) standards. By incorporating safety rated limit switches into their systems, industries can demonstrate their commitment to safety and avoid hefty fines or legal consequences resulting from non-compliance.

In addition to enhancing safety and compliance, safety rated limit switches can also improve efficiency in industrial processes. When limit switches operate reliably, machines can run smoothly without interruptions caused by false alarms or unexpected downtime. This leads to increased productivity and reduced maintenance costs, ultimately benefiting the bottom line of businesses.

In conclusion, safety rated limit switches play a crucial role in promoting safety and efficiency in industrial settings. By providing an extra layer of protection through rigorous testing and reliable operation, these switches help prevent accidents and injuries while also aiding compliance with regulatory standards. As industries continue to prioritize safety measures, incorporating safety rated limit switches into their systems should be at the forefront of their strategies.