check

check

check

check

Title: Enhancing Accuracy and Efficiency of Laser Sensor Positioning

In the realm of industrial automation and robotics, accurate and efficient laser sensor positioning is crucial for achieving optimal performance and productivity. With the advancement of technology, there has been a significant improvement in the design and functionality of laser sensors, making them an indispensable tool for various applications. This article explores the importance of laser sensor positioning, its various types, and how it can be used to enhance accuracy and efficiency in industrial settings.

Introduction to Laser Sensor Positioning

Laser sensor positioning involves the use of laser technology to determine the position, orientation, and distance of objects or surfaces in real-time. These advanced sensors are capable of providing highly accurate measurements with minimal error, making them a popular choice among industrialists and researchers alike. In this article, we will delve deeper into the world of laser sensor positioning, exploring its various applications and discussing ways to optimize its performance.

Types of Laser Sensors

There are several different types of laser sensors available in the market, each designed to meet specific needs and requirements. Some of the most common types include:

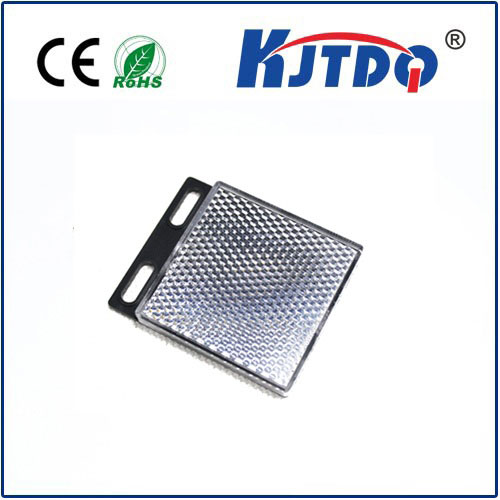

1. Reflective Laser Sensors: These sensors work by reflecting light off the surface being measured and analyzing the resulting pattern. They are highly sensitive and can detect even the slightest changes in light intensity.

2. Time-of-Flight (ToF) Laser Sensors: These sensors use high-speed cameras and pulsed lasers to measure the time lag between when a laser pulse is sent and when it returns. By calculating this delay, they can determine the distance between the sensor and target object.

3. Sidereal Optical Sensors: These sensors use a rotating mirror to capture light from the sun or other celestial bodies and analyze its path to determine the object's position relative to the Earth's axis.

Optimizing Laser Sensor Performance

Despite their advanced features, laser sensors can sometimes experience issues that affect their accuracy and efficiency. Here are some tips on how to optimize their performance:

1. Cleanliness: Ensure that the sensor's surface is clean, free from dust, dirt, or scratches, as these can interfere with the laser beam's reflection or absorption.

2. Placement: Place the sensor at a stable location with minimal movement or vibration, as any fluctuations can cause errors in measurement.

3. Power Supply: Provide the sensor with a stable power supply that meets its specifications to ensure consistent performance over time.

4. Software Settings: Adjust the software settings accordingly to account for environmental factors such as temperature, humidity, or air pressure that may affect the sensor's output.

Conclusion

In conclusion, laser sensor positioning is a critical component in many industrial processes, enabling machines to navigate accurately and efficiently within complex environments. By understanding the different types of laser sensors available and optimizing their performance through proper maintenance and software settings, manufacturers can achieve higher levels of accuracy and productivity while reducing costs associated with downtime or rework. As technology continues to advance, we can expect even more innovative applications of laser sensor positioning in various industries, further enhancing efficiency and productivity across the board.