check

check

check

check

Title: The Versatile SWT1635 Limit Switch: Enhancing Machine Performance and Efficiency

The SWT1635 limit switch is a crucial component in the world of automation, offering a reliable and efficient solution for monitoring and controlling machinery movements. This article delves into the features, benefits, and applications of the SWT1635 limit switch, highlighting its importance in enhancing machine performance and efficiency.

Introduction

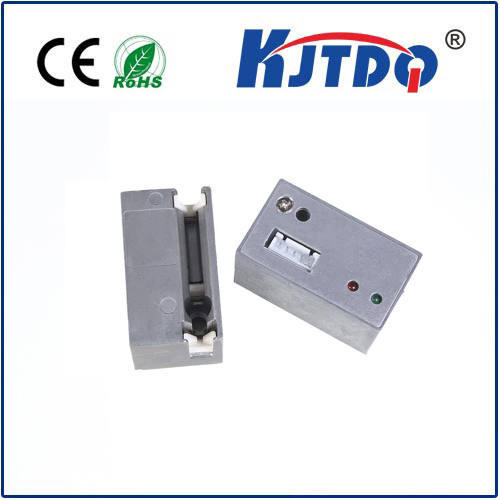

The SWT1635 limit switch is a versatile device designed to detect the presence or absence of an object, mechanical position, or motion within a given system. Its compact design, high reliability, and ease of integration make it an essential component in various industrial applications. By providing accurate feedback on the position or movement of mechanical parts, the SWT1635 limit switch helps optimize machine operations, reduce downtime, and improve overall productivity.

Key Features of the SWT1635 Limit Switch

The SWT1635 limit switch boasts several key features that contribute to its effectiveness and popularity. These include:

1. Compact and robust design: The SWT1635 limit switch is small in size yet built to withstand harsh environments, making it suitable for use in challenging industrial settings.

2. High durability: Made from high-quality materials, this switch can endure prolonged exposure to dust, moisture, and other contaminants without affecting its performance.

3. Accurate detection: With precise sensing capabilities, the SWT1635 limit switch ensures reliable detection of objects or mechanical positions, reducing errors and improving operational accuracy.

4. Easy installation and maintenance: The switch's straightforward design allows for quick and hassle-free installation, while its minimal maintenance requirements ensure long-term performance without frequent interventions.

Benefits of Using the SWT1635 Limit Switch

The SWT1635 limit switch offers numerous benefits that enhance machine performance and efficiency. Some of these benefits include:

1. Improved machine uptime: By providing accurate feedback on mechanical positions, the SWT1635 limit switch helps prevent unexpected downtime caused by misaligned parts or faulty mechanisms.

2. Reduced maintenance costs: With its durable construction and minimal maintenance requirements, the SWT1635 limit switch reduces repair and replacement costs over time.

3. Increased safety: The switch's ability to accurately detect and control machinery movements helps prevent accidents and injuries caused by malfunctioning equipment.

4. Versatility: Due to its compact size and adaptability, the SWT1635 limit switch can be integrated into various types of machinery across different industries, making it a valuable asset for manufacturers looking to streamline their operations.

Applications of the SWT1635 Limit Switch

The versatility of the SWT1635 limit switch makes it applicable in a wide range of industries and applications. Some common examples include:

1. Automation systems: In assembly lines and conveyor belts where precise positioning is critical, the SWT1635 limit switch ensures accurate alignment and movement of components.

2. Packaging equipment: By monitoring the position of packaging materials and products, the switch helps maintain consistency and quality in packaging processes.

3. Material handling devices: In cranes, hoists, and other lifting equipment, the SWT1635 limit switch provides crucial feedback on load positioning and movement.

4. Control panels: In industrial控制面板, the switch serves as an input device for monitoring process variables such as temperature, pressure, or flow rate.

Conclusion

The SWT1635 limit switch plays a significant role in enhancing machine performance and efficiency by providing accurate feedback on mechanical positions and movements. Its compact design, high durability, easy installation, and broad applicability make it an indispensable component in various industrial settings. By incorporating the SWT1635 limit switch into their machines, manufacturers can enjoy improved uptime, reduced maintenance costs, increased safety, and greater overall productivity.