check

check

check

check

Title: Understanding the Role of Worm Drive Limit Switch in Mechanical Systems

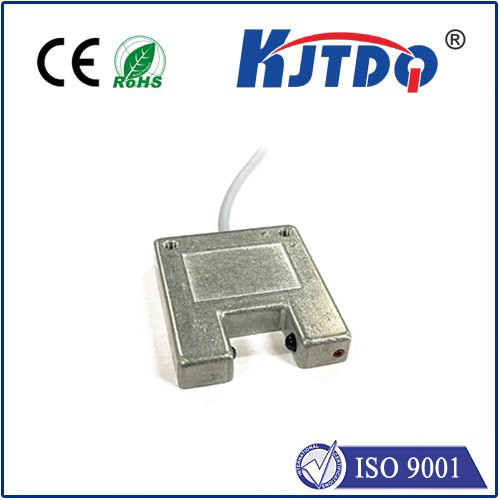

In mechanical systems, worm drive limit switches play a crucial role in controlling the movement of gears and other rotating parts. These devices use a worm, which is a long, cylindrical object that rotates along an axle inside a gear or motor. The worm drive limit switch consists of a movable contact that is designed to engage with the worm when it reaches a specific position, signaling to the system that it should stop moving.

One key advantage of using a worm drive limit switch is that it is highly precise and consistent. The movable contact can be adjusted to fit the exact size and shape of the worm, ensuring a secure and reliable connection between the two components. This makes it possible to achieve extremely accurate control over the motion of the gear or motor, even in applications where slight variations in speed or direction could have significant consequences.

Another benefit of worm drive limit switches is their simplicity and ease of use. Unlike other types of switches, such as push buttons or levers, worm drive limit switches do not require any additional components or mechanisms to operate. They simply need to be installed in the correct location and then adjusted to the desired setting. This makes them ideal for use in a wide range of industrial and commercial applications, from manufacturing machines to transportation systems.

Despite their many advantages, however, worm drive limit switches are not without their limitations. One potential challenge is ensuring that they are installed and maintained properly to prevent damage or failure. This may involve careful attention to detail when aligning the movable contact with the worm, as well as regular inspection and testing to ensure that everything is working as expected.

In addition, some applications may require more advanced features or functions than what is typically offered by standard worm drive limit switches. For example, some customers may need to customize their switches to include additional safety features, such as over-current protection or automatic shut-off in case of emergency. In these cases, it may be necessary to work closely with the manufacturer or supplier to develop a customized solution that meets the specific needs of the application.

Overall, however, worm drive limit switches are a powerful tool for controlling the movement of rotating parts in mechanical systems. With their precision, simplicity, and versatility, they offer a cost-effective and reliable solution for a wide range of applications. As technology continues to evolve, it is likely that we will see even more innovative designs and capabilities emerge for these essential components.