check

check

check

check

Exploring the Limit Switch for CNC Machines: An Indispensable Component in Precision Machining

In the realm of precision machining, the role of Computer Numerical Control (CNC) machines cannot be overstated. These advanced tools have revolutionized manufacturing processes by enabling unparalleled accuracy and efficiency in producing complex components. A critical aspect that contributes to the success of CNC machines is the limit switch – an often overlooked but fundamentally important component. In this article, we will delve into the significance of the limit switch for CNC machines, understanding its functions, and how it ensures optimal performance and safety in industrial applications.

The Fundamentals of Limit Switches in CNC Machines

A limit switch in a CNC machine serves as an electronic device that detects the presence or absence of an object. It operates on the principle of physically actuated contacts to manage the machine's motion, preventing it from moving beyond its designed limits. By doing so, it safeguards both the machine and the workpiece from potential damage or collision.

Understanding Limit Switch Functions

Limit switches perform several crucial functions within a CNC system. They are primarily used for homing and limiting purposes. Homing refers to the process where the machine finds its reference point or “home” position before starting a job. This step is essential for ensuring accurate cutting paths and avoiding errors. On the other hand, limiting prevents axes from moving too far, which could result in equipment damage or personal injury.

Types of Limit Switches for CNC Machines

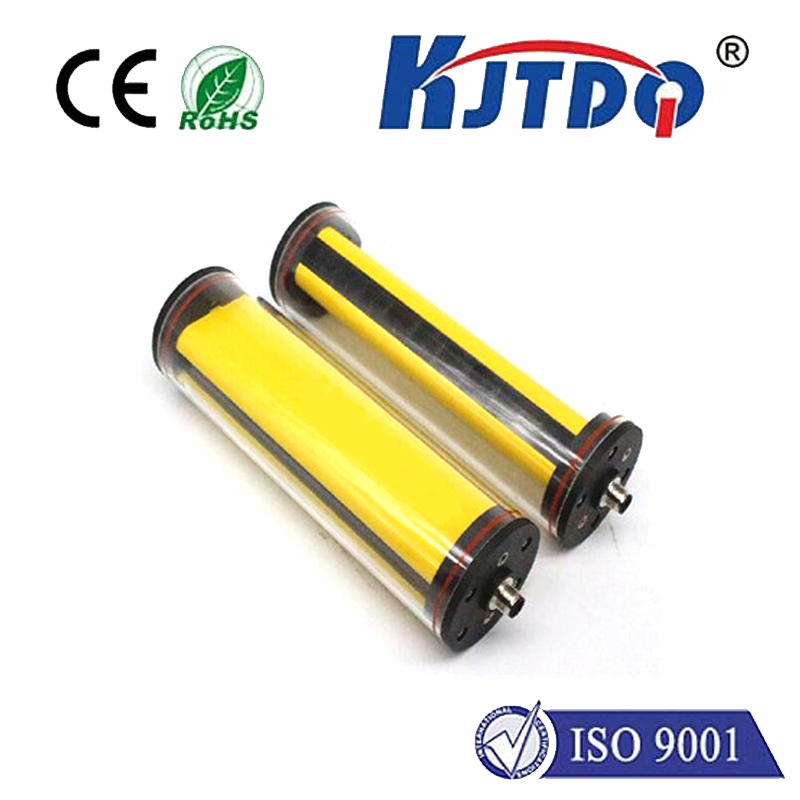

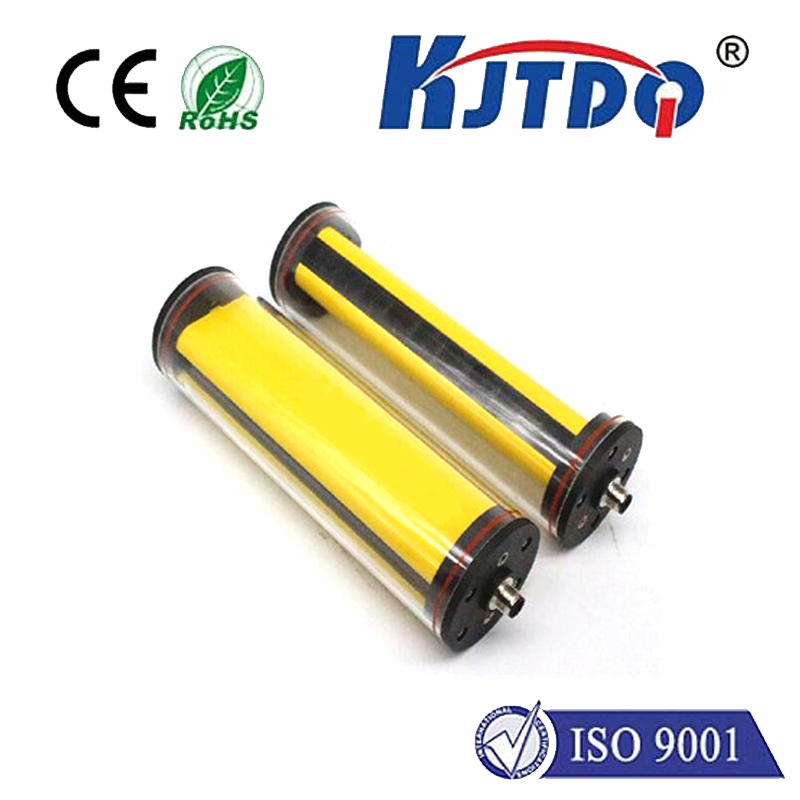

There are various types of limit switches designed for different applications within CNC machines. Mechanical limit switches use physical contact to trigger, whereas optical limit switches employ beams of light. Additionally, magnetic proximity sensors detect metal targets without touching them. Each type offers unique advantages depending on the specific needs of a machine setup.

Ensuring Optimal Performance

To maintain peak performance, CNC operators must regularly check and maintain their limit switches. This includes cleaning them to remove debris that might interfere with correct functioning and verifying that they are appropriately aligned. Software settings should also be reviewed periodically to ensure that the switches are communicating accurately with the CNC control system.

Importance of Limit Switches in Safety Protocols

Beyond enhancing productivity, limit switches play an integral part in safety protocols. They provide a fail-safe mechanism that immediately halts machine movement if parameters are exceeded. This feature is vital in environments where machinery operates at high speeds and precise tolerances, protecting both operators and equipment from harm.

Integration into Smart Manufacturing Systems

With the advent of Industry 4.0 and smart manufacturing, limit switches have become even more integrated into intelligent systems. Modern CNC machines can communicate real-time data about limit switch statuses to networked systems, allowing for predictive maintenance and optimization of production processes.

Conclusion

As we have seen, the limit switch for CNC machines is far more than a mere component; it is an indispensable element that guarantees precision, optimizes performance, and ensures safety in the fast-paced world of CNC machining. By understanding its functions and implementing proper maintenance practices, manufacturers can harness the full potential of their CNC machines, driving their businesses forward with confidence and reliability