check

check

check

check

Compressor Limit Switch: A Fundamental Component in Hydraulic Systems

The compressor limit switch is a crucial component of any hydraulic system. It serves as an automatic shutdown mechanism that prevents overloading and protects the system from damage. In this article, we will explore the role of the compressor limit switch in hydraulic systems, its working principle, and common types and applications.

I. Introduction to the Compressor Limit Switch

A. Definition and Function

B. Importance in Hydraulic System Protection

II. Working Principle of the Compressor Limit Switch

A. How it Works

B. Components and Parts Involved

C. Control Signals and Communication

III. Types and Applications of Compressor Limit Switches

A. Mechanical Limit Switches

1. Pros and Cons of Mechanical Limit Switches

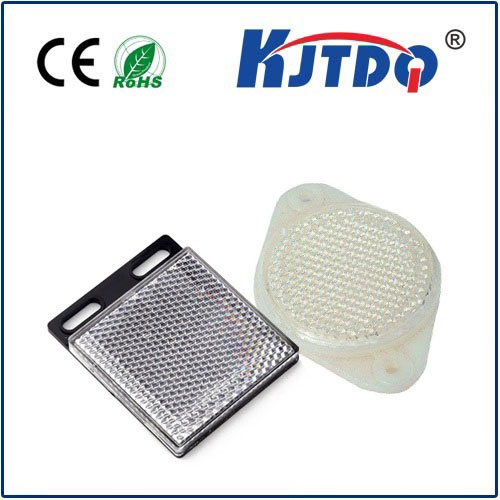

2. Common Types and Features

3. Applications in Different Industries

B. Electronic Limit Switches

1. Advantages and Disadvantages of Electronic Limit Switches

2. Features and Characteristics

3. Applications in Various Industries

IV. Troubleshooting and Maintenance of Compressor Limit Switches

A. Significance of Regular Maintenance

B. Common Issues and Solutions for LimitSwitches

1. Problematic Behaviors and Causes of Malfunctions

2. Recommended Methods for Repairing and Replacing Limit Switches

C. Best Practices for Maintaining Limit Switches for Longevity and Performance

1. Proper Installation Techniques

2. Regular Inspections and Testing Procedures

3. Proper Storage and Handling of Limit Switches

D. Future Trends and Developments in the Compressor Limit Switch Industry

1. Advances in Technology and Innovations in Limit Switch Design

2. Emerging Applications and Market Demands for Limit Switches

3. Potential Impacts on the Future of Hydraulic Systems and Industries Reliant on Them.