check

check

check

check

Title: The Essential Components of Rotary Limit Switches and Their Applications

Rotary limit switches are essential components in various industrial and mechanical devices. They help to detect the rotation of a shaft or the movement of a mechanism and provide feedback to control systems. This article explores the basic principles behind rotary limit switches, their construction, and their different applications.

1. Introduction to Rotary Limit Switches

A rotary limit switch is a type of sensor that is designed to detect the rotation of a shaft or the movement of a mechanism. It consists of a movable contact that is brought into contact with the shaft or mechanism when it rotates. The contact can be either magnetic or electric, depending on the type of switch being used. When the shaft or mechanism stops rotating, the contact is released, and an electrical signal is generated to indicate the stop position.

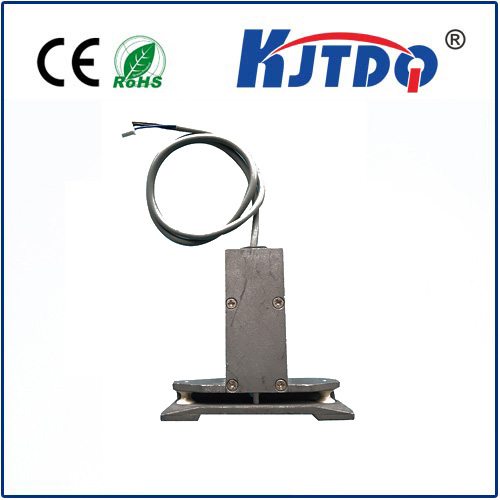

2. Construction of Rotary Limit Switches

Rotary limit switches come in different configurations, but most consist of four main components: the switch body, the contact, the spring, and the plunger. The switch body houses the contact and provides a housing for the plunger. The spring helps to maintain tension on the contact when the shaft or mechanism is moving. The plunger is attached to the switch body and is moved by the force generated by the shaft or mechanism.

3. Types of Rotary Limit Switches

There are several types of rotary limit switches available, each with its own unique features and applications. Some common types include:

a) Check Switches: These are simple switches that use a metal slider to detect the rotation of a shaft or mechanism. They are commonly used in automotive and aircraft applications.

b) Recessed Switches: These switches have a recessed contact that fits into a hole in the switch body. They are designed for use in applications where shaft or mechanism rotation must be detected without damaging the surrounding hardware.

c) Magnetic Switches: These switches use a magnetic field to detect the rotation of a shaft or mechanism. They are commonly used in industrial settings where high levels of dust or debris may interfere with the operation of other types of switches.

d)Optical Switch: These switches use light to detect the rotation of a shaft or mechanism. They are commonly used in applications where accurate positioning and control are critical, such as in medical equipment or robotics.

4. Applications of Rotary Limit Switches

Rotary limit switches have numerous applications in various industries and fields, including:

a) Industrial Automation: Rotary limit switches are widely used in industrial automation systems to monitor and control machine motion, speed, and position. They are also used to trigger other devices or processes when certain conditions are met.

b) Automotive Industry: Rotary limit switches are crucial components in automobile engines and transmissions, helping to detect errors in gear selection and engine speed. They are also used in brake systems to prevent accidents caused by excessive braking.

c) Aerospace Industry: Rotary limit switches are essential for monitoring and controlling flight systems in airplanes and spacecraft. They help to ensure safe and reliable flight operations by providing real-time feedback on system performance.

d) Medical Technology: Rotary limit switches are used in medical devices such as surgical instruments, ventilators, and patient monitors. They help to ensure precise positioning and control during complex surgical procedures or critical medical situations.