check

check

check

check

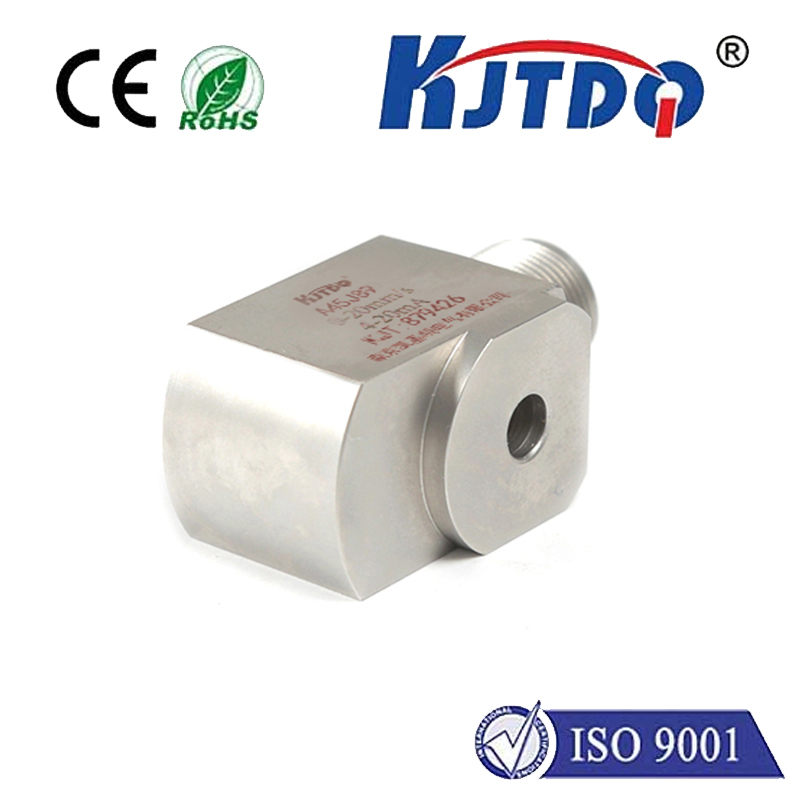

1️⃣️Check whether the label sensor position is correct

Before debugging the tag sensor, you first need to confirm whether the position of the tag sensor is correct. Ensure that the label sensor is aligned with the label position to avoid angular deviation between the sensor and label.

2️⃣️Adjust label sensor sensitivity

Tag sensor sensitivity is a key factor affecting the debugging effect. According to the actual application requirements, the sensitivity of the label sensor is reasonably adjusted so that it can accurately detect the position of the label.

3️⃣️Adjust the height of the label sensor

Adjust the height of the label sensor according to the label size so that the sensor can correctly identify the height of the label. Ensure that the distance between the tag sensor and the tag is appropriate to avoid being too close or too far from affecting the debugging effect.

4️⃣️Adjust the label sensor angle

The angle adjustment of the label sensor is also an essential link. By adjusting the angle of the tag sensor, it can accurately identify the position and angle of the tag. According to the actual application scenario, the angle of the sensor is reasonably adjusted to meet actual needs.

5️⃣️Check the tag sensor connection line

The connection line of the tag sensor is also one of the key factors affecting the debugging effect. Before debugging, you need to check whether the connection lines of the tag sensors are correct to avoid sensor failure or malfunction.

6️⃣️Conduct tag sensor test

In order to ensure the accuracy and stability of tag sensor debugging, tag sensor testing is required. Through testing, the performance and stability of the tag sensor can be verified to ensure that it can work properly under different environmental conditions.